In the era of digital commerce, the value of in-person experiences cannot be overstated. This is why Waterline, a leader in industrial cooling solutions, invites you to step into any of our Customer Experience Centers located around the the region. Here visitors can immerse themselves in the cutting-edge technology that Waterline offers, understanding firsthand how these systems manage to keep industrial environments efficiently cool.

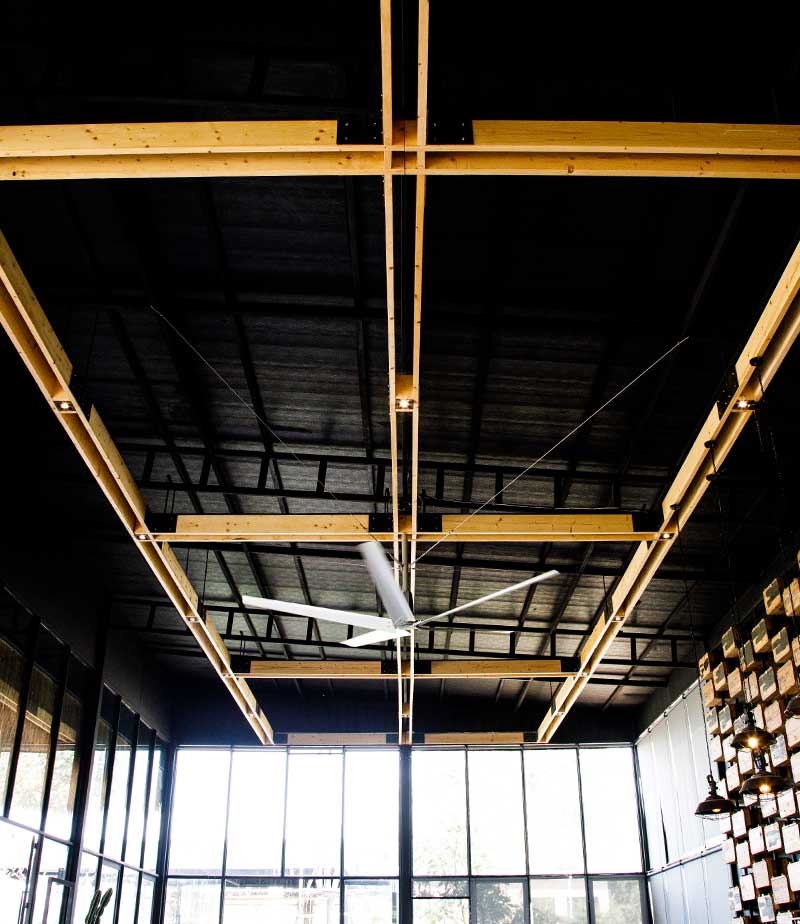

Industrial ceiling fans, renowned for boosting airflow and temperature management in sizable spaces like factories, warehouses, and distribution hubs, bring advantages that surpass mere functionality, greatly influencing architectural and building design. In this article, we will delve into the influence of industrial ceiling fans on architectural and building design, and how they can amplify a space's aesthetic appeal.

In the realm of industrial cooling, several choices lay on the table. One such widely embraced option is industrial ceiling fans. Nevertheless, considering the escalating energy costs and the importance of eco-friendly operations, the energy efficiency of these fans deserves a careful study against other cooling systems. This article presents a comprehensive evaluation of the energy efficiency of industrial ceiling fans as compared to other prevalent cooling mechanisms, enabling you to make an informed selection.

Warehouses and distribution centers form the backbone of supply chains, yet their vastness and towering ceilings pose significant challenges. Ensuring a comfortable temperature and maintaining high air quality are paramount for employee health, product preservation, and overall well-being. High-Volume, Low-Speed (HVLS) fans have emerged as a widely adopted solution for ventilation and cooling in such vast spaces. In this article, we explore the advantages that HVLS fans bring to warehouses and distribution centers.

Within the food and beverage sector, ensuring a sanitary and secure environment is paramount. Industrial ceiling fans are gaining traction as a practical approach to augment air quality and heighten energy efficiency in food and beverage processing facilities. The popularity of these fans stems from their ability to reduce energy expenditures, lower contamination risks, and elevate employee comfort. This article elucidates the merits of using industrial ceiling fans in food and beverage processing facilities, emphasizing their potential to enhance both air quality and energy efficiency.

High Volume Low Speed (HVLS) fans are vital assets in industrial and commercial spaces such as warehouses and manufacturing plants, circulating large amounts of air efficiently. Two key types of motors power these fans: AC (Alternating Current) and DC (Direct Current), each possessing distinctive characteristics that influence their performance and application appropriateness.

HVLS fans, or High Volume Low Speed fans, are industrial-grade fans built to circulate large volumes of air at relatively slow speeds. Their prime utilization lies in big open spaces like warehouses and manufacturing units, offering a slew of benefits. This article dives into the diverse environments where HVLS fans can be effectively used.

High Volume Low Speed (HVLS) fans are widely used in expansive spaces like warehouses and manufacturing facilities to enhance temperature and air quality. Despite their advantageous features, understanding their safety aspects is crucial when considering their usage. This article explores key safety features inherent in HVLS fans and the importance of proper installation and usage.

HVLS fans, also known as High Volume Low Speed fans, are specifically engineered industrial fans that efficiently circulate air in large indoor areas such as warehouses, factories, and sports arenas. These fans, notable for their vast size and slow blade speed, facilitate a broad dispersion of air across wide areas. HVLS fans stand out as a cost-friendly and energy-conserving means to augment comfort and air quality in large indoor environments.

HVLS fans, or High Volume Low Speed fans, are specially designed industrial fans that effectively circulate large volumes of air at lower speeds. They find primary use in extensive open spaces like warehouses, manufacturing facilities, enhancing the overall temperature control and air quality. This article unravels the key advantages of implementing HVLS fans in your space.

Roof exhaust fans are a crucial element of any industrial facility, as they help to regulate the temperature and air quality within the space. Whether you're running a factory, warehouse, or any other type of industrial facility, having a properly functioning roof exhaust fan is essential for the health and safety of your employees and the overall efficiency of your operation.

Improving working conditions for staff workers is a crucial aspect of any business. A positive and supportive work environment can increase productivity, employee satisfaction, and overall success. In contrast, poor working conditions can lead to high turnover rates, decreased productivity, and even legal issues. Therefore, it is essential for businesses to prioritize the well-being of the workers, safety, and a comfortable work environment.

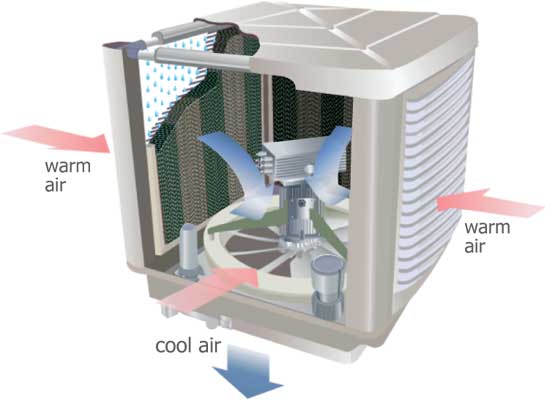

Industrial evaporative cooling, also known as EVAP, is a process that uses the natural cooling process of evaporation to lower the temperature of the air. It is a cost-effective and environmentally friendly alternative to traditional air conditioning systems and is particularly effective in dry, hot climates. EVAP systems are commonly used in industrial facilities such as factories, warehouses, and power plants to improve the comfort of the employees working in the space and increase the overall efficiency of the operation.

Cooling down a factory can be a challenging task, especially during the hot summer. Industrial facilities often generate a lot of heat due to machinery. As a result, it is essential to find economical and efficient ways to keep the temperature at a comfortable level. This not only helps to improve the comfort of the employees working in the facility but also helps to improve the overall efficiency and productivity of the operation.

In industrial environments, maintaining optimal temperature and humidity levels is important for the comfort and productivity of employees. Poor air circulation and extreme temperatures can lead to discomfort and decreased productivity, which can impact the overall efficiency and profitability of the facility. Evaporative cooling systems are an effective solution for improving the air circulation and temperature in industrial settings, which can lead to improved comfort and productivity for employees.

In industrial environments, maintaining optimal temperature and humidity levels is important for the comfort and productivity of employees. Poor air circulation and extreme temperatures can lead to discomfort and decreased productivity, which can impact the overall efficiency and profitability of the facility. Evaporative cooling systems are an effective solution for improving the air circulation and temperature in industrial settings, which can lead to improved comfort and productivity for employees.

Factory areas can get extremely hot, especially during the summer months. This can lead to decreased productivity and discomfort for workers. It is important to find ways to cool down these areas to create a comfortable and safe work environment. Here are some ways to cool down factory areas.

Air ducts play a crucial role in the heating, ventilation, and air conditioning (HVAC) systems of industrial facilities. They are used to distribute cool air throughout the space, helping to regulate the temperature and improve the air quality. There are many types of air ducts available, including PIP air ducts and traditional galvanized tubes. While both options are good, PIP air ducts offer several advantages over galvanized tubes.

Air change is the process of introducing fresh air into a space, either through natural ventilation or mechanical ventilation. This process can be especially important in factories, where the air quality can be affected by a variety of factors, such as emissions from machinery, dust and dirt from materials, and other contaminants. In this article, we will explore how air change can improve the factory in terms of air quality, comfort, and productivity.